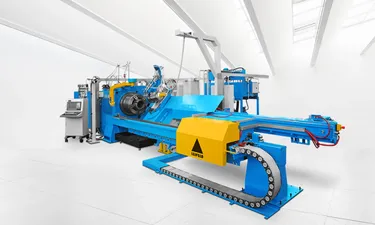

Leifeld SC 310

Spinning Center

High precise forming, large flexibility, compact machine design.

Metal forming is a key technology that significantly determines the development and performance of our modern industry. From the automotive industry to hydrogen applications, lighting, wind energy, oil & gas, food & chemical industry and aerospace – components manufactured by metal forming machines can be found everywhere. In this demanding field, Leifeld Metal Spinning GmbH has established itself as one of the leading machine tool manufacturers in special machine construction with the LEIFELD and NIHON SPINDLE brands. With over 130 years of experience and team members worldwide, we develop individual solutions for chipless metal forming in your industry!

Metal fabrication tools such as spinning and flow forming machines form metals without cutting, i.e. without material loss. In contrast to machining processes (e.g. milling or turning), that produce chips, the metal is permanently deformed by targeted pressure during chipless forming – for example in the form of a round blank or a preform that forms the desired contour when rotated around a forming mandrel. The material therefore flows under force along a predetermined shape – precisely, efficiently and gently. Depending on the metal forming process, heat and special tools are also used to optimize the forming behavior. This results in rotationally symmetrical components made from a wide variety of materials ideal for applications with special requirements in terms of dimensional accuracy, weight, stability and cost-effectiveness.

As an internationally experienced manufacturer of metal forming machines, we at LEIFELD have been developing and manufacturing innovative and application-specific solutions that set standards worldwide since 1891. You too can rely on our expertise in metal forming machinery!

145

133

749

12,259

LEIFELD metal forming machinery is more than just technology – it is a key to value creation and process innovation. Our metal fabrication tools enable companies to implement new production routes, increase their productivity and set themselves apart from the competition in the long term.

Every industry places individual demands on spinning and forming machines. That is why we at LEIFELD focus on maximum flexibility, in-depth process understanding and customer orientation. We are proud to make a significant contribution to the further development of various industries worldwide with our metalworking machinery.

Thanks to our intensive development work, our close exchange with customers and our in-house team of experts, we create innovative machines for industrial metal shaping that outperform conventional processes and are precisely tailored to our customers' requirements. Over 145 patents and numerous tried-and-tested Industry 4.0 applications are proof of our innovative edge.

We also have a globally unique application center where all forming machines can be experienced under one roof. Here, customers have the opportunity to test a wide variety of metal forming machines live. Furthermore, they have the chance to manufacture prototypes and small series or carry out tests and trials under real conditions. The center also serves the continuous research and development of new solutions for chipless metal forming.

From the initial consultation, component design and process development to simulations, machine installation, commissioning and after-sales service: We support our customers holistically – competently, reliably and in a spirit of partnership

Spinning Center

High precise forming, large flexibility, compact machine design.

Wheel Spinning Center

Designed for manufacturing forged aluminium wheels for trucks.

Necking-in machine

High performance necking-in machine with front loading.

Our service is not an add-on, but a central element of our value proposition. We provide our customers worldwide with comprehensive support: from precise machine diagnostics and predictable maintenance packages to reliable spare parts management and preventive maintenance solutions. Together with our customers, we develop individual maintenance concepts to minimize downtimes and ensure the long-term efficiency of your production. Training courses, either at your premises or at our headquarters in Ahlen, ensure that your machine operators can use their systems efficiently and optimally.

Quality, innovation and reliability have always been the foundation of our business. Under the motto #metalperfected, we not only supply cutting-edge technology for your metal forming process – we think ahead. Our teams of experts offer sound advice, practical solutions and personal support throughout the entire life cycle of your metal forming machinery. This results in long-term partnerships based on trust and technological leadership.

In metal spinning, a rounded blank is transformed into a rotationally symmetrical hollow body by chipless forming with a rotating spinning roller. The preform is clamped against a spinning chuck and gradually formed with a spinning roller until it reaches the final contour. Additional processing such as flanging or cutting off edges can be carried out in the same clamping.

In flow forming, a cylindrical or conical preform – typically a tube – is pushed onto a mandrel and clamped. Several rotating flow forming rollers press synchronously from the outside against the workpiece, causing the material to expand in an axial direction: the wall thickness is reduced and the workpiece is lengthened. Variants such as forward and backward flow forming also allow internally toothed parts to be produced.

Shear Forming is an incremental forming process from the spinning family, in which a rotating blank or preform is axially stretched or tapered in an overflow along the tool contour. The material is precisely shaped into the desired cylindrical or conical outer contour by spinning rollers.

In profiling, grooves, notches or complex shapes are created in a preform in several steps using rotating tools. The most important variants are the splitting, bending and rolling processes. Hub forming and slotting are also associated with profiling technology.

During necking-in, the material is drawn into a mold under rotation to create precise inner contours or indentations. The process enables uniform and precise shaping, particularly in the area of diameter reductions and wall thickness gradients.

Flow Forming and flow forming machines work according to the principle of plastic deformation of metals. This means that the metal is deformed under the influence of high forces in such a way that it permanently changes its shape without removing any material. This process, also known as chipless metal forming, is particularly efficient as it minimizes material losses and often requires no additional post-processing steps. The machines can therefore efficiently process metals such as steel, copper or aluminum.

A typical machine for metal forming consists of several essential components:

A crucial aspect of metal forming is the precise control of the entire process. LEIFELD metal forming machines are equipped with state-of-the-art technology that enables precise control of the force, speed and position of the tools.

From day one, we have supported our customers as an innovative machine tool manufacturer. We develop, manufacture and sell state-of-the-art machines that are used worldwide for metalworking in various industries. Innovation and precision always take center stage. We take a holistic approach to forming technology and master complex challenges with innovative solutions.

With more than 200 employees at locations in Germany, the USA, China and Japan as well as a global network of sales and service partners, we have a worldwide presence and support our customers locally with comprehensive services. Rely on the expertise of a company that has been a leader in metal forming for over a century and secure a decisive advantage in your industry. Order the metal forming machines of your choice with patented technology from LEIFELD now! In addition, we also offer used machines and retrofit solutions to make proven LEIFELD quality available in different price segments. Our used machines are carefully modernized and adapted to current standards so that they can be optimally integrated into existing production processes – contact us now!

Are you interested in distributing our industry-leading machines in your region? Learn more about our partner program today!

Become an official sales distributor

Distribute innovative machine tools

Receive attractive commission